Damage to Conductors - BSEN 60669-1 / BS 5733.

BSEN 60669-1 clause 12.2.5.

Screw-type terminals shall be so designed and constructed that they clamp the conductor(s) without undue damage to the conductor(s).

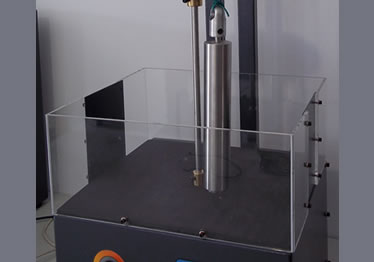

Our equipment Damage to Conductor was designed and manufactured to perform the test specified in many standards (IRAM 60884-1, BSEN 60669-1, BS 5733) to the damage to conductors.

Our Damage to Conductor Test Apparatus is fully automated, controlled by microcontroller.

You only should set:

- The time test.

Making the test:

- Place the sample in the test sample holder support.

- Place the wire in the sample and pass it through the hole in the plate assay.

- Place the corresponding weight (or the set of weights to reach the required weight).

- Turn on the equipment.

- Go to the screen test and press the START key to start the test.

- Adjust the speed with the knob.

- Press PAGE key if you want to reset the lap counter and time.

- The machine automatically stops when it reaches the time set on the equipment test.

| Glow Wire Test Apparatus specifications: | |

|---|---|

| Power Supply: |

|

| All: |

|

| You can see: |

|

| Dimensions: |

|

| According to: |

|